MORPHOLOGY OF Ni-TiN/Si3N4 COMPOSITE COATINGS AT HIGH-TEMPERATURE OXIDATION

Abstract

Electrodeposited nickel coating has excellent physical and mechanical properties, however it does not withstand to high temperature oxidation for long time. The addition of nitride phase within the nickel based coating improve the oxidation resistance through dense surface morphology improvement. A preliminary study was performed to investigate the high temperature oxidation behavior on the coating morphology after exposed at high temperature. The Ni-TiN/Si3N4 composite coatings deposited at electrodeposition temperature of 35 ℃, 40 ℃ and 50 ℃. The electrolyte consists of 0.17 M NiCl2.6H2O, 0.38 M Ni2SO4.6H2O, 6 g/L TiN, 0,6 g/L Si3N4, 40 g/L H3BO3, 0,6 g/L Sodium Dodecyl Sulfate (SDS). High temperature oxidation process on the samples was performed by heating at temperature of 700 ℃ for 2 hours within air conditions. The morphology and composition samples were characterized by using SEM/EDS. In general, the result showed that the morphology of Ni-TiN/Si3N4 composite coatings became rough due to the oxidation process. Elements coating such as Ni, Ti, Si and N were disappeared after the oxidation process due to the outward diffusion process.

Keywords

Full Text:

PDFReferences

Yuantao Z, Lianbo W, Yanle S, Huabing L, Chuanhai J, Vincent J, Wenge L. Influences of Al and Ti particles on microstructure, internal stress and property of Ni composite coatings. J. Alloys Compounds. 2019; 793: 314-325.

Nikolaus J, Michael M, Michal Z, Stefan S, Hynek H, Farwah N, Jaakko J, Martin R, Jozef K, Christian M, Rostislav D. Impact of Si on the high-temperature oxidation of AlCr(Si)N coatings. J. Mater. Sci. Technol. 2022; 100: 91–100.

Esmar B. High temperature oxidation resistance of nickel-/nitride composite coatings: A brief review: AIP Conf. Proc. 2021; 2320: 030007.

Quansheng M, Liuhe L, Ye X, Xuan M, Yi X and Hongtao L. Int. J. Refrac. Metals and Hard Mater. 2016; 59: 114-120.

Baehrea D, Ernst A, Weißhaar K, Natter H, Stolpe M, and Busch R. Electrochemical Dissolution Behavior of Titanium and Titanium-based Alloys in Different Electrolytes. Procedia CIRP. 2016; 42: 137 – 142.

Menghua W, Weiping J and Pengxiang L. Electrodepositing Ni-TiN nanocomposite Layers with Applying Action of Ultrasonic Waves. Procedia Eng. 2017; 174: 717 – 723.

Garner A, Frankel P, Partezana J and Preuss M. The effect of substrate texture and oxidation temperatureon oxide texture development in zirconium alloys. J. Nuclear Mater. 2017; 484: 347-356.

Benjamin G, Xabier M, Mathias C.G, Gilles B, Fernando P. Mechanisms of hot corrosion of pure nickel at 700°C: Influence of testing conditions. Corr. Sci. 2018; 141: 211-220.

Abishek B.K, Hirdayesh S, Emily S, Murali S. Experimental Study on the Porosity of Electrochemical Nickel Deposits. Procedia Manufac. 2017; 10: 478 – 485.

Quansheng M, Liuhe L, Ye X, Xuan M, Yi X, Hongtao L. Effect of Ti content on the microstructure and mechanical properties of TiAlSiN nanocomposite coatings. Int. J. Refrac. Metals and Hard Mater. 2016; 59: 114-120.

Shujiang G, Fuhui W, Sam Z. High temperature oxidation behavior of a sputtered pure Ni nanocrystalline coating at 700–900 °C Surf. Coat. Technol. 2003; 167: 212–216.

Fafeng X, Liu C, Wang F, Wu M.H, Wang J.D, Fu H.L. and Wang J.X, Preparation and characterization of Nano Ni–TiN coatings deposited by ultrasonic electrodeposition. J. Alloys and Compounds. 2010; 490: 431–435.

Chunyang M, Wanying Y, Minzheng J, Wei C, Fafeng X. Jet pulse electrodeposition and characterization of Ni–AlN nanocoatings in presence of ultrasound. Cerr. Int. 2018; 44: 5163-5170.

Changjie F, Shuilian H, Yuanfei J, Namei W, Mingsheng L, Shenglong Z. Fuhui W, Li X. Effects of Si content on microstructure and mechanical properties of TiAlN/Si3N4-Cu nanocomposite coatings. Appl. Surf. Sci. 2014; 320: 689–698.

Alexander, W. B., Wenjian, Z., Yasir, J.N., Gillian, R. and Philip, N.B. Temperature effects on the electrodeposition of semiconductors from a weakly coordinating solvent. J. Electroanalytical Chem. 2023; 944: 117638.

Zhu, X., Cai, C., Zheng, G., Zhang, Z. and Li, J. Electrodeposition and corrosion behavior of nanostructured Ni-TiN composite films. Trans. Nonferrous Met. Soc. China. 2011; 21: 2216-2224.

Esmar, B., Leli, K., Widyaningrum, I., Iwan, S., Teguh, B.P., Hadi, N. and Riser, F. Mechanical and Tribology Properties of electrodeposited Ni-TiN/Si3N4 Composite Coatings. Mater. Sci. Forum. 2022; 1057: 218-226.

Leli, K., Esmar, B., Iwan, S. Pengaruh Temperatur Terhadap Pembentukan Lapisan Komposit Ni-Tin/Si3N4 Dengan Menggunakan Metode Elektrodeposisi. Prosiding Seminar Nasional Fisika (E-Journal). 2019; 8: SNF2019-PA-27-32.

H. Kyung and C.K. Kim. Microstructural evolution of duplex grain structure and interpretation of the mechanism for NiO scales grown on pure Niand Cr-doped substrates during high temperature oxidation. Mater. Sci. and Eng. 2000; B76: 173–183.

Nikolaus, J. Farwah, N., Rostislav D., Michael M., Jaakko, J., Michal, Z., Martin R., Stefan, S., Jozef, K., Hynek, H., and Christian M. J. Mater. Sci. & Technol. 2022; 100: 91–100.

Dorota, K., Martin, W., Erdmann, S. Early stages of high-temperature oxidation of Ni- and Co-base model superalloys: A comparative study using rapid thermal annealing and advanced electron microscopy. Corr. Sci. 2021; 191: 109744.

Chen, W., Li, Q., Zhou, L., Qiu, W., Ren, Y., Li. C., Chen, J., Lin, Y., Zhou, K. Oxidation mechanism of a near β-Ti Alloy. Mater. & Design. 2022; 223: 111144.

Y. Yin et al. Thermal oxidation roperties of titanium nitride and titanium–aluminum nitride materials — A perspective for high temperature air-stable. Thin Solid Films. 2007; 515: 2829–2832.

DOI: https://doi.org/10.18860/neu.v16i1.21044

Refbacks

- There are currently no refbacks.

Copyright (c) 2023 Esmar Budi

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Published By:

Physics Study Pragramme, Faculty of Science and Technolgy, Universitas Islam Negeri (UIN) Maulana Malik Ibrahim Malang, Indonesia

B.J. Habibie 2nd Floor

Jl. Gajayana No.50 Malang 65144

Telp./Fax.: (0341) 558933

Email: neutrino@uin-malang.ac.id

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

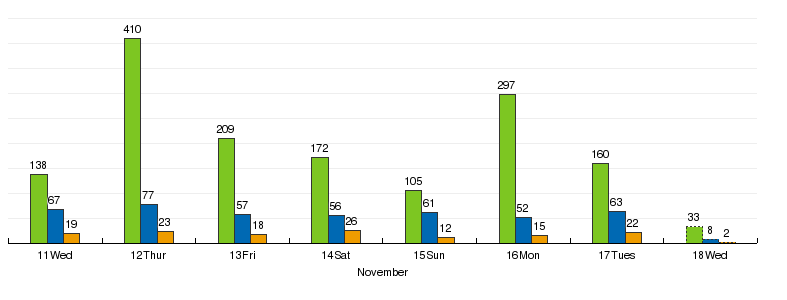

View My Stats