UTILIZATION OF BANANA FROND BRIQUETTE CHARCOAL AS AN ALTERNATIVE TO ENVIRONMENTALLY FRIENDLY TECHNOLOGY

Abstract

The purpose of this study is the use of banana frond briquette charcoal as an alternative to environmentally friendly technology. This type of research is an experiment. Experimental data collection techniques, documentation, and literature studies. The data analysis method in this study uses a quantitative approach. Banana frond briquettes are divided into 3 groups: A (81% banana frond charcoal: 19% adhesive), B (71% banana frond charcoal: 29% adhesive), and C (91% banana frond charcoal: 9% adhesive). The results of the banana frond briquette test on the C sample of 91% charcoal briquettes with 9% adhesive showed the best results with a calorific value of 4571 kcal/kg. The study concluded that the best calorific value in sample C with a charcoal composition of banana fronds was 91%; 9% adhesive was 4571 cal/kg.

Keywords

Full Text:

PDFReferences

1. Maulidian O, Nur Wahyuni P, Pujiastuti C, Urip Widodo L, Edahwati L. Study on Increasing the Calorific Value of Blotong Briquettes with the Addition of Banana Fronds and Molasses. Vol. 16, Journal of Chemical Engineering. 2022.

2. Sembodo BS, Hamdan Prayogi F. E K U I L I B R I U M Decomposition of Banana Fronds into Glucose Thermochemically in Hot Compressed Water. 2013;

3. Vachlepi A, Didin D, Balai S, Sembawa P, Raya J, Km PB. Penggunaan Biobriket Sebagai Bahan Bakar Alternatif Dalam Pengeringan Karet Alam Usage of Bio-briquette as Alternative Fuel on Natural Rubber Drying. 2013.

4. Maharani F, Kurniawan E, Ginting Z. Making Briquettes from Wood Sawdust Charcoal with Cassava Flour Adhesive as an Alternative Fuel. Vol. 11, Journal of Chemical Technology Unimal. 2022.

5. Sari Harahap N, Jumiati Material Physics E, Physics J, Science and Technology F, Islam Negeri Sumatra Jl Lap Golf U, Tengah K, et al. Analysis of Physical and Chemical Properties of the Making of Salak Seed Waste Charcoal Briquettes with Variations of Tapioca Flour and Sago Flour Adhesives. 2023; 12(1):116–24. Available from: https://doi.org/10.25077/jfu.12.1.116-124.2023

6. Masthura, M. Physical Analysis and Combustion Rate of Biochar Briquettes from Banana Frond Materials. Elkawnie. June 29, 2019; 5(1):58.

7. Saparin Eka Sari Wijianti. Utilization of Organic Waste for Making Briquettes as Alternative Energy for Community Needs in Kulur Ilir Village, Central Bangka Regency. 2023;

8. Imam Ardiansyah, Yandra Putra A, Sari Y. Analysis of Calorimeter Calorimeter Value of Various Types of Biomass Briquettes. Journal of Research and Education Chemistry. 2022 Dec 24; 4(2):120.

9. Iskandar N, Nugroho S, Meta D, Feliyana F, Sudharto J. Faculty of Engineering-Wahid Hasyim University Semarang 103 Quality Test of Coconut Shell Charcoal Briquettes Based on SNI Quality Standards. Momentum. 2019; 15(2):103–8.

10. Chusniyah DA, Pratiwi R, Benyamin B, Suliestyah S. Quality Test of Briquettes Made of Coconut Bage Charcoal Based on Moisture Content Value. Journal of Research and Scientific Works, Trisakti University Research Institute. 2022 Jan 31; 7(1):14–23.

11. Setyono MYP, Yayok Suryo Purnomo. Analysis of Moisture Content and Ash Content of WWTP Mud Briquettes and Fly Ash with the Addition of Wood Sawdust. Insology: Journal of Science and Technology. 2022 Dec 30; 1(6):696–703.

12. Saputra M, Razi F, Mehra Erfiza N. Bio Charcoal Briquettes from a Mix of Straw Biomass and Coffee Peel. Scientific Journal of Agricultural Students [Internet]. 2022; 7(4). Available from: www.jim.unsyiah.ac.id/JFP

13. Rahmadani FHFHH. Making Oil Palm Leaf Charcoal Briquettes (Elaeis Guineensis Jacq). With sago starch adhesive (Metroxylon Rott). 2017;

14. Aljarwi MA, Pangga D, Ahzan S. Test of Combustion Rate and Calorific Value of Rice Husk Wafer Briquettes with Pressure Variations. 2020; 6(2).

15. M. Afif Almu Syahrul. Yesung Allo Padang. Analysis of calorific value and combustion rate in mixed briquettes of 9calophyllm inophyllum seeds and rice husk ash. 2014;

DOI: https://doi.org/10.18860/neu.v16i2.26743

Refbacks

- There are currently no refbacks.

Copyright (c) 2024 Veni Efriyani Efriyani

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Published By:

Physics Study Pragramme, Faculty of Science and Technolgy, Universitas Islam Negeri (UIN) Maulana Malik Ibrahim Malang, Indonesia

B.J. Habibie 2nd Floor

Jl. Gajayana No.50 Malang 65144

Telp./Fax.: (0341) 558933

Email: neutrino@uin-malang.ac.id

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

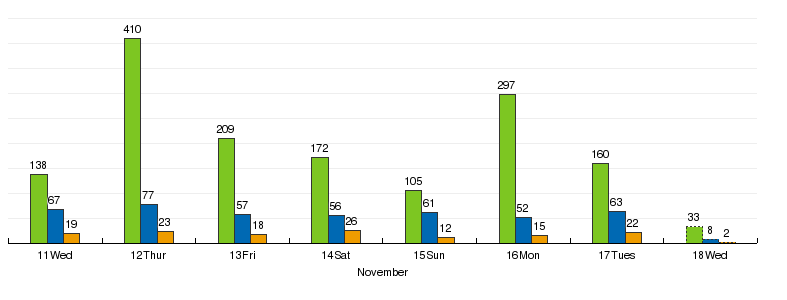

View My Stats