CHARACTERIZATION OF CARBON NANOCRISTRAL STRUCTURE BASED ON CORN COB CHARCOAL

Abstract

Keywords

Full Text:

PDFReferences

Sun Y, Webley PA. Preparation of activated carbons from corncob with large specific surface area by a variety of chemical activators and their application in gas storage. Chem Eng J. 2010;162(3):883–92.

Liu X, Pan L, Lv T, Zhu G, Sun Z, Sun C. Microwave-assisted synthesis of CdS-reduced graphene oxide composites for photocatalytic reduction of Cr(vi). Chem Commun. 2011;47(43):11984–6.

Sun G, Wan J, Sun Y, Li H, Chang C, Wang Y. Enhanced removal of nitrate and refractory organic pollutants from bio-treated coking wastewater using corncobs as carbon sources and biofilm carriers. Chemosphere. 2019;237:124520.

Hockett EA. Handbook of cereal science and technology. In: Kulp K, Ponte Jr J, editors. Handbook of Cereal Science and Technology. New York: Marcel Dekker; 2000. p. 81–125.

Shenderova OA, Zhirnov V V., Brenner DW. Carbon nanostructures. Crit Rev Solid State Mater Sci. 2002;27(3–4):227–356.

Ditzel FI, Prestes E, Carvalho BM, Demiate IM, Pinheiro LA. Nanocrystalline cellulose extracted from pine wood and corncob. Carbohydr Polym. 2017;157:1577–85.

Rosi M, Abdullah M, Khairurrijal. Sintesis Nanopori Karbon dari Tempurung Kelapa sebagai Elektroda pada Superkapasitor. Nano. 2009;(January):6–8.

Yu J, Zhao Y, Li Y. Utilization of corn cob biochar in a direct carbon fuel cell. J Power Sources. 2014;270:312–7.

Polytechnic K. Production of Activated Carbon from Corncobs and its Utilization in Crude Oil Spillage Clean Up. 2008;1–9.

Arancon RA, Barros HR, Balu AM, Vargas C, Luque R. Valorisation of corncob residues to functionalised porous carbonaceous materials for the simultaneous esterification/transesterification of waste oils. Green Chem. 2011;13(11):3162–7.

Yu F, Steele PH, Ruan R. Microwave pyrolysis of corn cob and characteristics of the pyrolytic chars. Energy Sources, Part A Recover Util Environ Eff. 2010;32(5):475–84.

Wang X, Xing W, Feng X, Yu B, Lu H, Song L, et al. The effect of metal oxide decorated graphene hybrids on the improved thermal stability and the reduced smoke toxicity in epoxy resins. Chem Eng J. 2014;250:214–21.

Li ZQ, Lu CJ, Xia ZP, Zhou Y, Luo Z. X-ray diffraction patterns of graphite and turbostratic carbon. Carbon N Y. 2007 Jul;45(8):1686–95.

Zhou Q, Cai W, Zhang Y, Liu J, Yuan L, Yu F, et al. Electricity generation from corn cob char though a direct carbon solid oxide fuel cell. Biomass and Bioenergy. 2016;91:250–8.

Yuwita PE, Mas’udah KW, Sunaryono, Taufiq A. Structural, morphological, and functional group analysis of corncob powder. AIP Conf Proc. 2020;2251(August).

Guo M, Wang G, Zhao Y, Li H, Tang K, Zhao Y, et al. Preparation of Nano-ZrO2 powder via a microwave-assisted hydrothermal method. Ceram Int. 2021;47(9):12425–32.

Liu Y, Zhao X, Li J, Ma D, Han R. Characterization of bio-char from pyrolysis of wheat straw and its evaluation on methylene blue adsorption. Desalin Water Treat. 2012;46(1–3):115–23.

Mas’Udah KW, Nugraha IMA, Abidin S, Mufid A, Astuti F, Darminto. Solution of reduced graphene oxide synthesized from coconut shells and its optical properties. AIP Conf Proc. 2016;1725(April 2016).

Lutterotti L. MAUD tutorial-instrumental broadening determination. Departimento di Ing dei Mater Univ …. 2006;1–18.

Güler Ö, Boyrazlı M, Başgöz Ö, Bostancı B. The synthesis of carbon nanostructures from tea plant wastes. Can Metall Q. 2017;56(3):349–59.

DOI: https://doi.org/10.18860/neu.v15i1.17067

Refbacks

- There are currently no refbacks.

Copyright (c) 2022 Pelangi Eka Yuwita, Roihatur Rohmah

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Published By:

Physics Study Pragramme, Faculty of Science and Technolgy, Universitas Islam Negeri (UIN) Maulana Malik Ibrahim Malang, Indonesia

B.J. Habibie 2nd Floor

Jl. Gajayana No.50 Malang 65144

Telp./Fax.: (0341) 558933

Email: neutrino@uin-malang.ac.id

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

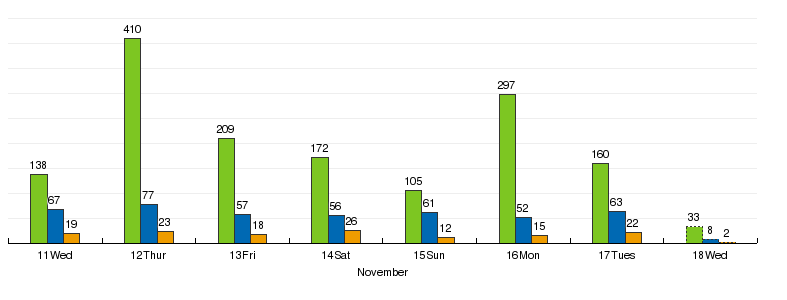

View My Stats