DEVELOPMENT OF RS-WZ3 SENSOR IN IOT BASED VIBRATION MONITORING SYSTEM

Abstract

Keywords

Full Text:

PDFReferences

1. Marsick A, André H, Khelf I, Leclère Q, Antoni J. Benefits of Mann–Kendall trend analysis for vibration-based condition monitoring. Mech Syst Signal Process. 2024;216:111486.

2. Rusinski E, Czmochowski J, Moczko P, Pietrusiak D. Monitoring and testing of high power industrial fans vibration. Procedia Eng. 2017;199:2190–5.

3. Nithin SK, Hemanth K, Shamanth V. A review on combustion and vibration condition monitoring of IC engine. Mater Today Proc. 2021;45:65–70.

4. Rusnaldy R, D Setiawan J, Arivian A. Monitoring Kondisi Pahat dengan Sinyal Getaran pada Proses Bubut.

5. Zaira JY, Wijianto A. Analisa Getaran Mesin Milling Vertikal 1108 Terhadap Pengaruh Variasi Kedalaman Potong. J Elem Vol. 2020;6(1).

6. Wang H, Ye X, Yin M. Study on predictive maintenance strategy. Int J u-and e-Service, Sci Technol. 2016;9(4):295–300.

7. Shukla K, Nefti-Meziani S, Davis S. A heuristic approach on predictive maintenance techniques: Limitations and scope. Adv Mech Eng. 2022;14(6):16878132221101008.

8. Zou H. Application of piezoelectric self powered wireless sensor in CCAL vibration environment monitoring. Results Eng. 2023;20:101492.

9. Dewi RK, Indrasari W, Firmansyah H. KARAKTERISASI SENSOR PIEZOELEKTRIK LDT0-028K UNTUK PERANCANGAN SISTEM PENGUKURAN GETARAN PADA MESIN. In: PROSIDING SEMINAR NASIONAL FISIKA (E-JOURNAL). 2024.

10. Gawde S, Patil S, Kumar S, Kamat P, Kotecha K. An explainable predictive maintenance strategy for multi-fault diagnosis of rotating machines using multi-sensor data fusion. Decis Anal J. 2024;10:100425.

11. Romanssini M, de Aguirre PCC, Compassi-Severo L, Girardi AG. A review on vibration monitoring techniques for predictive maintenance of rotating machinery. Eng. 2023;4(3):1797–817.

12. Villarroel A, Zurita G, Velarde R. Development of a low-cost vibration measurement system for industrial applications. Machines. 2019;7(1):12.

13. Alshehri A, Gardonio P, Elliott S, Zilletti M, Kraft M. Experimental evaluation of a two degree of freedom capacitive MEMS sensor for velocity measurements. Procedia Eng. 2011;25:619–22.

14. Achmadi R, Indrasari W, Firmansyah H. KARAKTERISASI SENSOR KAMERA TERMAL AMG8833 UNTUK PERANCANGAN SISTEM PENGUKURAN TEMPERATUR PADA MESIN. In: PROSIDING SEMINAR NASIONAL FISIKA (E-JOURNAL). 2024.

15. C S dan T. RS-WZ3 / WZ1-N01-1 Temperature vibration transmitter user’s manual. 2017.

16. Bkheet SA, Agbinya JI. A review of identity methods of internet of things (IOT). Adv Internet Things. 2021;11(4):153–74.

17. Al Qorni W, Azhar A, Yuniarti E. Perancangan Sistem Kontrol Otomatis Berbasis Web Menggunakan Raspberry Pi 3 pada Smarthome. Al-Fiziya J Mater Sci Geophys Instrum Theor Phys. 2019;1(2):15–24.

18. Widodo S, Kristiantoro T. Teknologi Micro Electro Mechanical Systems. In: PROSIDING SEMINAR NASIONAL FISIKA (E-JOURNAL). 2014. p. 321–33.

19. Tosin T. Perancangan dan Implementasi Komunikasi RS-485 Menggunakan Protokol Modbus RTU dan Modbus TCP Pada Sistem Pick-By-Light. Komputika J Sist Komput. 2021;10(1):85–91.

DOI: https://doi.org/10.18860/neu.v17i1.28442

Refbacks

- There are currently no refbacks.

Copyright (c) 2024 Widyaningrum Indrasari

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License.

Published By:

Physics Study Pragramme, Faculty of Science and Technolgy, Universitas Islam Negeri (UIN) Maulana Malik Ibrahim Malang, Indonesia

B.J. Habibie 2nd Floor

Jl. Gajayana No.50 Malang 65144

Telp./Fax.: (0341) 558933

Email: neutrino@uin-malang.ac.id

This work is licensed under a Creative Commons Attribution-NonCommercial-ShareAlike 4.0 International License

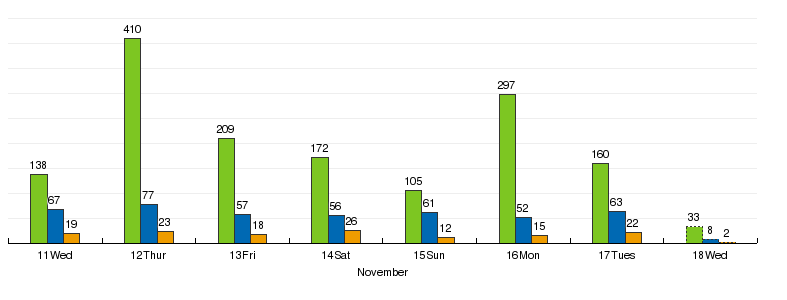

View My Stats